A Flexible Packaging Comparison.

As your bar brand grows and you look for scalable (aka: larger run) solutions, you'll likely hear the term "cold seal film or packaging". Usually from your co packer or machine provider.

What exactly does that mean? Well, with the naked eye, it's not really all that different from heat sealable film. In fact if you go to any grocery store, the biggest bar and snack brands use cold seal packaging....probably never thought about it.

It has more to do with the performance and machineability. Cold seal allows you to run fast, therefore making it the optimum solution for larger runs.

Important note: Most brands that we work with don't have that scalability but are working with co packers that exclusively run cold seal on their equipment. Wrap'N'Roll doesn't provide cold seal solutions at this time, unless the runs are in millions and millions. (which is not usually the case with most of our customers.)

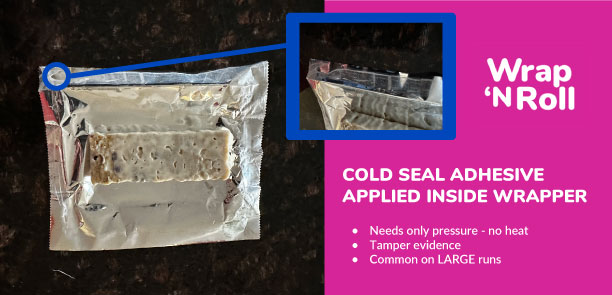

Sealing Process:

Cold Seal Film: Utilizes pressure-sensitive adhesives that do not require heat to create a seal. The sealing process occurs at room temperature by applying pressure.

Heat Seal Film: Requires heat to activate the adhesive and create a bond between the film layers. Heat is applied to melt the adhesive, and upon cooling, a strong seal is formed.

Temperature Sensitivity:

Cold Seal Film: Does not require elevated temperatures, making it suitable for heat-sensitive products like chocolates, candies, or heat-sensitive coatings on snack bars.

Heat Seal Film: Involves the application of heat, which may not be suitable for products that are sensitive to high temperatures.

Speed of Production:

Cold Seal Film: Generally considered faster in terms of production speed since it does not rely on heat activation. This can be advantageous for high-speed packaging lines.

Heat Seal Film: May have slightly longer sealing times due to the heat activation process.

Suitability for Product Types:

Cold Seal Film: Ideal for packaging products that are sensitive to heat, such as chocolate bars or energy bars with heat-sensitive coatings.

Heat Seal Film: Suitable for a wide range of products, including snacks with various textures and consistencies.

Seal Strength:

Cold Seal Film: Offers a secure and tight seal, especially suitable for products that do not require an extremely strong bond.

Heat Seal Film: Provides a strong and durable seal, making it suitable for products that need a more robust packaging solution.

Packaging Design:

Cold Seal Film: Can be advantageous for packaging designs that require intricate patterns or graphics since there is no risk of heat affecting the printing.

Heat Seal Film: May be limited in terms of intricate designs due to the heat involved in the sealing process.

Packaging Line Compatibility:

Cold Seal Film: Well-suited for high-speed packaging lines due to its quick and efficient sealing process.

Heat Seal Film: May require adjustments in packaging line settings to accommodate the heat-sealing process.

Ultimately, the choice between cold seal film and heat seal film depends on the specific requirements of the snack bar and the desired characteristics of the packaging for the product.

Leave your comment